ProLogium Leads the Way to Solid-State Battery Commercialization

TAIPEI, Taiwan, Aug. 20, 2025 (GLOBE NEWSWIRE) -- “A battery that will not self-ignite, offers the world’s highest conductivity, can be mass-produced, and is cost-competitive is no longer a castle in the air.”

Against the backdrop of a global energy transition and rapidly evolving battery safety standards, solid-state battery technology has emerged as a focal point for the battery industry’s future. ProLogium‘s recent launch of the world’s first mass-producible GEN 4 solid-state lithium ceramic battery platform, marks a critical step from laboratory innovation to large-scale commercial deployment.

At the heart of this breakthrough is ProLogium’s proprietary SF-Ceramion Superfluidized All-Inorganic Solid-State Electrolyte, completing the final piece of the solid-state lithium ceramic battery puzzle. The innovation delivers a mass-production platform that unites scalability, manufacturability and cost competitiveness. This leap extends beyond electrolyte innovation to encompass cell architecture, manufacturing processes, and equipment systems— a holistic transformation that showcases ProLogium’s integrated and systematic R&D capabilities.

Leveraging years of technological expertise and a rich/deep global patent portfolio, ProLogium has established a GWh-scale demonstration plant in Taoyuan, Taiwan, with stable shipments already underway. Leveraging the expertise developed via that plant, ProLogium is moving ahead strongly towards the launch of its gigafactory in Dunkirk, France, to localize supply chains and scale up production. The GEN 4 platform achieves excellence in Safety × Performance × Cost × Mass Production, cementing ProLogium’s role as a benchmark and a value-chain cornerstone for the next-generation battery industry.

Founder & CEO Vincent Yang said: “Delivery is just the beginning. We’ve built a replicable, scalable industrial framework for solid-state lithium batteries. The next step is to refine it and align precisely with global market needs. Together with partners, we will accelerate commercialization and advance the entire value chain to full maturity.”

Architecture Definers: From Original Vision to Shared Industry Path

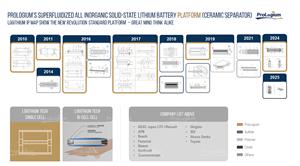

According to global patent database analysis, ProLogium began securing core solid-state battery architecture patents as early as 2010. To date, it has amassed over 286 international patents spanning cell structures (including single-cell and bipolar designs), related manufacturing processes, and supporting equipment. These innovations showcase ProLogium’s original technological prowess and establish a solid foundation for licensing, strategic alliances, and industry expansion.

In cell architecture design, ProLogium was the first to introduce multiple breakthrough concepts that defined the “industry-standard blueprint” for next-generation solid-state lithium batteries. In recent years, several international battery startups and automakers have unveiled stacking and packaging structures strikingly similar to ProLogium’s designs—evidence that this technical approach has become/established? an industry-wide consensus and a testament to the feasibility and foresight of ProLogium’s early innovations.

As the saying goes, “great minds think alike.” Today, this shared design logic is becoming the common language of the global solid-state battery sector, further cementing ProLogium’s leadership in cell structure design and process integration.

Caption:

Since 2010, ProLogium has been building a global patent moat around core solid-state lithium battery technologies, covering single-cell and bipolar structures, ceramic separators, and the integration of manufacturing processes and equipment. The timeline shows how ProLogium’s early patent directions have now become design paths now followed by major international players, validating both foresight and mass-production viability.

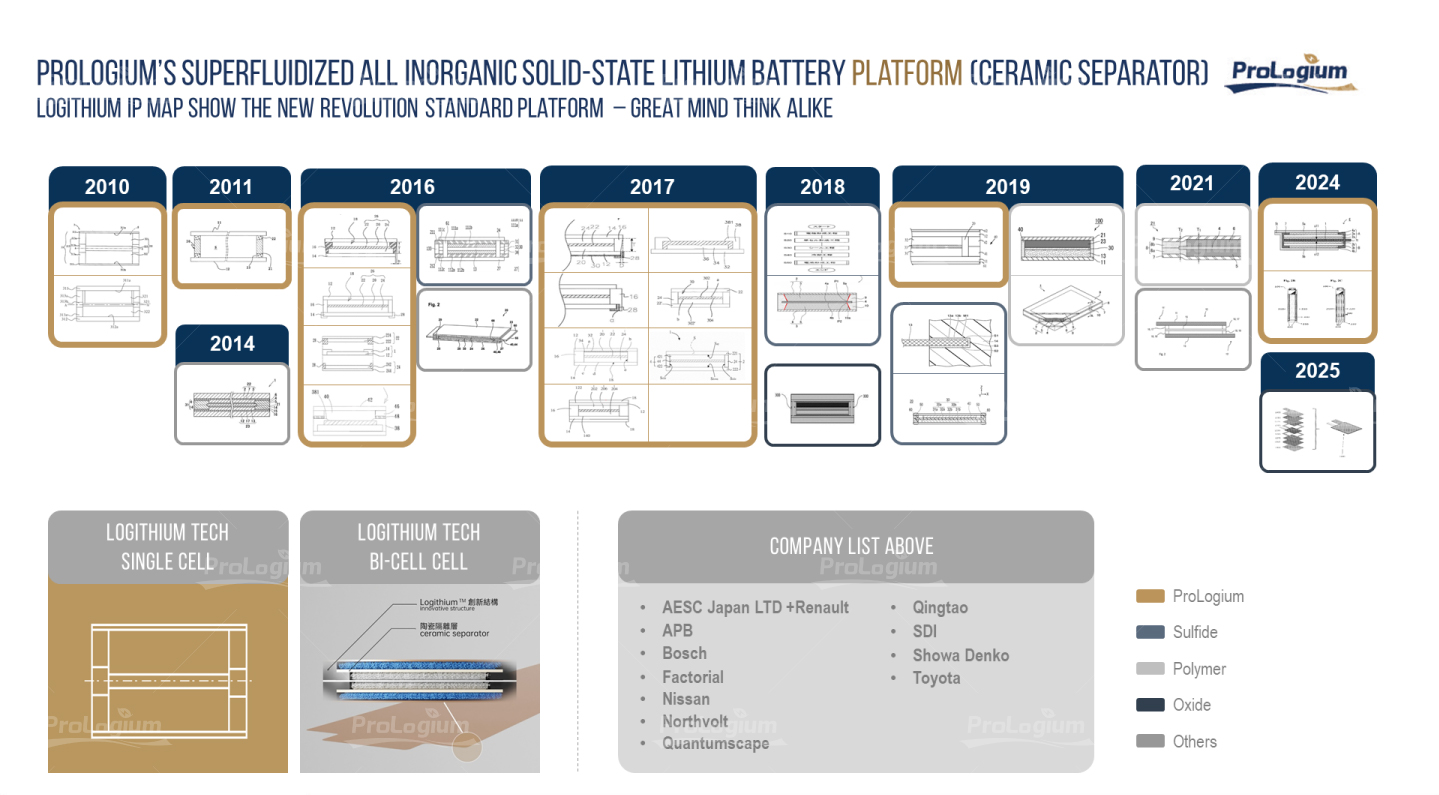

Caption:

Since 2017, ProLogium has expanded its patent coverage for bipolar cells (BiPolar+) and ceramic separator architectures, including structural designs, manufacturing methods, and system integration. Multiple global automakers have filed similar patents in recent years, further validating the foresight of ProLogium’s design approach and its emergence as a mainstream industry direction.

Facing the barriers to mass production of solid-state batteries, ProLogium has taken the lead in completing full-chain technology integration—from materials and cell architecture to processes and equipment. ProLogium has also advanced an open collaboration model, partnering with upstream and downstream partners to build a scalable and standardized industry value chain.

While most companies remain cautious about the feasibility of mass production, ProLogium's forward-looking, systematic deployment has already opened an important chapter in the commercialization of the solid-state battery.

From Trials to Mass Production: High Yields Prove Solid-State Battery Scalability

Where battery technology viability depends not only on lab results but also on stable, high-throughput, and consistent manufacturing performance, ProLogium has built a proven track record.

Since building its first 0.01 GWh sample line in 2013, ProLogium has upheld the belief that “from concept to reality—every innovation must deliver,” continuously accumulating production know-how.

From sheet-based to more manufacturing-efficient roll-based cells, ProLogium has developed EV-grade solid-state batteries with all-ceramic separators, increasing capacity from 10 Ah to 170 Ah. Since 2016, these batteries have been supplied to major European and Asian automakers for testing.

In 2017, the company established the world’s first pilot line for roll-to-roll all-ceramic separator solid-state batteries (250–330 mm width) and between 2018 and 2019, completed the world’s first on-road EV tests with WM Motor and Enovate, becoming one of the earliest in the industry to achieve mass-production-grade applications.

In 2023, ProLogium completed the world’s first 660 mm-wide, GWh-scale roll-to-roll solid-state battery production line—an important milestone in scalable manufacturing. By Q3 2024, the line had stably shipped over 500,000 solid-state lithium ceramic cells, proving its yield control and large-scale production stability. ProLogium also stands as the only company worldwide with both solid-state cells and modules certified for safety and electrical performance by TÜV, a leading independent testing body.

The Core Behind the Production: Innovative Materials Redefine the Manufacturing Universe

“Batteries are chemical engineering, not digital chips. Change the formula, and you must rebuild the entire manufacturing universe.” As Vincent Yang emphasizes, ProLogium develops materials not merely to make batteries, but to create manufacturing processes that integrate seamlessly into production lines.

Since 2010, ProLogium has been securing foundational patents for single-cell and bipolar module designs, laying the groundwork for industry standardization. In 2017, the company achieved a >90% yield rate on its automated pilot line, showcasing deep expertise in system integration and process control.

ProLogium’s Taoyuan demonstration plant has become a focal point for site visits from policymakers and industry partners worldwide reinforcing its role as a model for global solid-state battery mass production and a catalyst for industry-wide progress.

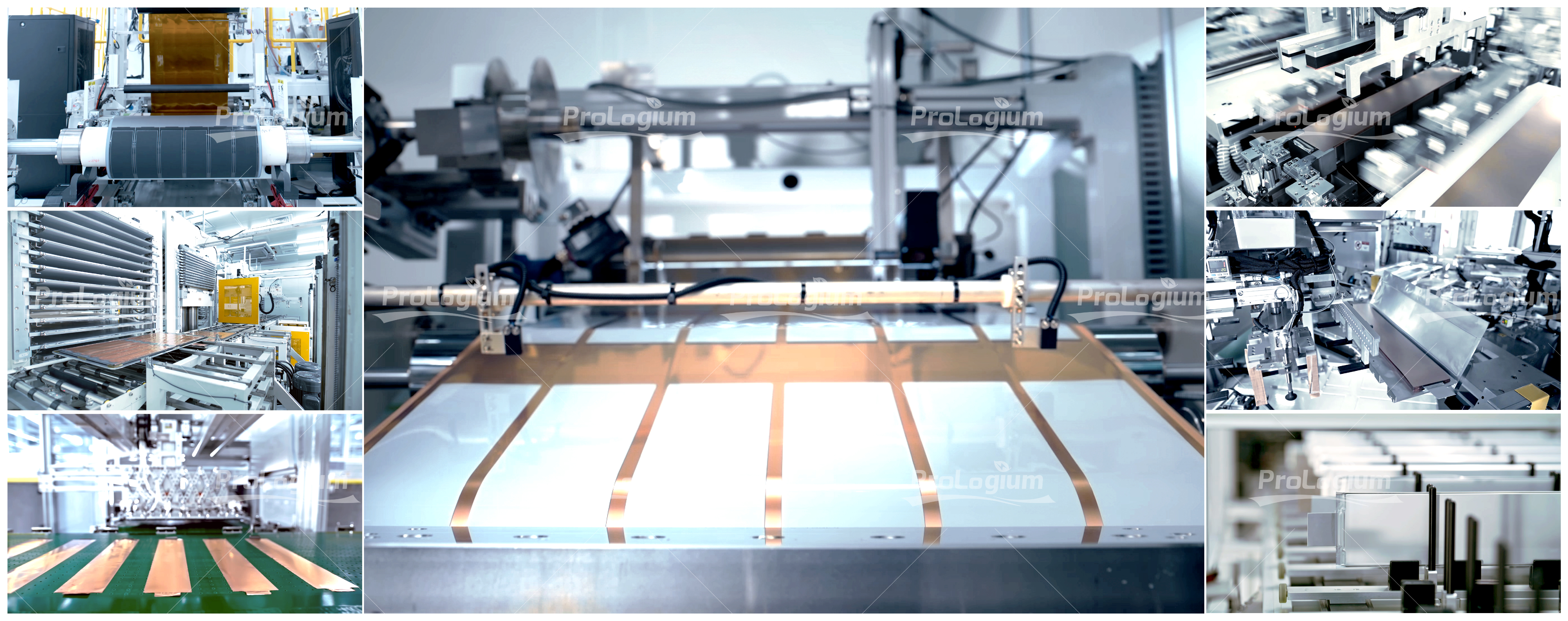

In 2024, ProLogium became the first company to publicly release a full video of a GWh-scale solid-state lithium ceramic battery production line, offering the industry an unprecedented, end-to-end manufacturing reference.

The video showcases each critical stage—from target-aligned printing and wet ceramic separator coating, to frame adhesive printing, cathode-anode alignment and lamination, inlay stacking without polymer separators, and pouch packaging without liquid electrolyte filling. This open demonstration not only validates the maturity and scalability of ProLogium’s technology but also provides the industry with a clear, systematic manufacturing framework

Caption:

ProLogium’s self-developed GWh-scale next-generation solid-state lithium ceramic battery production line integrates high-speed roll-to-roll ceramic coating (30–50 m/min), rotary adhesive coating (15–30 m/min), high-temperature/high-pressure lamination, and the world’s first modular Inlay unit design, achieving 0.1 sec/layer stacking and eliminating liquid electrolyte filling. This simplifies processes, boosts yields, and enhances safety. In 2024, revenue reached USD 5.3 million, up 134% year-on-year, validating both technical strength and global growth potential.

Cost advantage: Breaking the High-Cost Myth of Solid-State Batteries

Cost has long been seen as the final hurdle to large-scale commercialization of solid-state batteries. Despite their exceptional safety and electrochemical performance, all-inorganic solid-state batteries have been held back by expensive materials and complex processes, reinforcing the industry’s perception that they are too costly to scale.

ProLogium’s GEN 4 Superfluidized All-Inorganic Solid-State Electrolyte (SF Ceramion) breaks through this barrier with multiple innovations in material design and process integration. Compared to sulfide-based solid electrolytes, SF Ceramion significantly simplifies electrode fabrication, reduces dry room requirements, and enhances overall production scalability, unlocking a clear path to cost-competitive mass production.

Material costs for ProLogium’s SF Ceramion are only 3–5% of those for conventional sulfide systems, with the future potential to match the cost of liquid electrolytes. This is not just a theoretical improvement, but a result validated through engineering design and verified on a demonstration production line.

By combining material innovation with manufacturing-friendly processes, ProLogium has redefined the cost structure of the full production system for solid-state batteries, delivering a scalable, feasible, and economically viable commercialization pathway.

This electrolyte breakthrough, together with ProLogium’s decade-long progress in cell architecture and manufacturing platforms, enhances the integration, yield control, and production scalability of its GEN 4 solid-state lithium ceramic battery. It unlocks the cross-sector application potential across automotive, energy storage, defense, and aerospace applications.

Leading is Not About Being Different, It’s About Showing the World the Way Forward

From material invention and process design to patent strategy, equipment integration, mass production, and stable delivery, ProLogium has spent nearly two decades building a truly scalable battery future.

Today, as more global battery makers adopt manufacturing paths and structural designs pioneered by ProLogium, this “technological resonance” underscores the feasibility and foresight of its early innovations, solidifying its leadership in cell architecture, process integration, and equipment engineering.

The manufacturing capabilities demonstrated by the GEN 4 platform not only position ProLogium for global expansion but also create tangible value to end markets. Looking ahead, ProLogium will continue to work with industry partners and policymakers worldwide to accelerate the energy transition toward a safer, more efficient, and more sustainable low-carbon future.

About ProLogium Technology

Founded in 2006, ProLogium Technology is an energy innovation company dedicated to the R&D and manufacturing of next-generation lithium ceramic batteries. Its proprietary technologies are protected by over a thousand global patents (granted and pending). After introducing the world’s first next-gen battery with 100% ceramic separators in 2013, ProLogium has been at the forefront of the battery technology. In 2025, ProLogium once again leads the industry by launching the world’s first Superfluidized all Inorganic Solid-State Lithium Battery. ProLogium’s Gigafactory in Taoyuan, Taiwan came online in 2024 and has shipped more than 500,000 battery cells to date. This steady supply to the global market is a testimony of its technology readiness and mass production capability.

In May 2024, the company inaugurated its first overseas R&D center in Paris-Saclay, France, to provide tailored technological solutions for the European market. Its first overseas Gigafactory project, located in Dunkirk, France, successfully completed both environmental and construction permitting processes by the end of 2024. Construction is scheduled to begin in 2026, with mass production of fourth-generation batteries starting in 2028, ramping up to 4 GWh capacity by 2029, and full production by 2030.

Press Contacts:

Sam Chang, ProLogium Technology

Tel: 03-452-1991#18802

E-mail: sam@prologium.com

Sara Lin, ProLogium Technology

Tel: 03-452-1991#1880 6

E-mail: sara@prologium.com

Photos accompanying this announcement are available at:

https://www.globenewswire.com/NewsRoom/AttachmentNg/00d227ac-4ef8-4a4e-931c-bdbb6f4e4a57

https://www.globenewswire.com/NewsRoom/AttachmentNg/8c40f960-67a2-4b91-ad8f-18d44ee4c95f

https://www.globenewswire.com/NewsRoom/AttachmentNg/e8039f56-8598-4db3-8d34-d09a733470e4

A video accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/c9c616e9-a94f-4a6e-b96f-05969ba952cb

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.